Does your diesel tank comply with AS1940 Standards?

When handling combustible and flammable liquids complying with safety measures is an important priority across industry. There are strict manufacturing and design requirements within Australia to ensure site compliance and safety, all of which are found within the Australian Standards. For the fuel storage industry, the Australian Standard 1940 is the primary regulation outlining how to safely handle and store flammable liquids. In 2017 major amendments were made to this standard showcasing new safety and operational requirements for fuel sites and diesel tanks. The changes affect the design and manufacturing of fuel tanks, site operations and the maintenance of your diesel fuel tank. It is important therefore that both manufacturers and suppliers are aware of the major changes that impact their current on-site fuel storage solutions and impact future buying decisions

It’s important your diesel tank complies with the AS1940 as this standard provides requirements for the planning, design, construction, and safe operations of all installations in which flammable/combustible liquids are stored or handled. Here are the key areas your fuel tank must comply with:

Additional safety features with bunds

For containment and potential spillage, having a bunded wall is already an important safety feature in case of fuel leakage. The bund is an important safety feature as it contains any spillage within a secondary outer tank containment. Before the changes to AS1940 the spill containment of the secondary tank was at 100% capacity, with the introduction of the new standards increasing capacity to 110% of the largest tank.

Liquid Tank Levels

The introduction of safe fill levels is now mainstream across fuel tank providers with the AS1940 standard placing the limit of safe fill level to 95% of the tank’s capacity. Also, important to note that for above ground fuel storage tanks storing 5000L+ of a flammable liquid, a high-level alarm is now required as an additional safety feature. This is also applicable for above ground storage tanks storing combustible liquids, except the high-level alarm is required for 25,000l of liquid rather than 5000l.

GHS Alignment

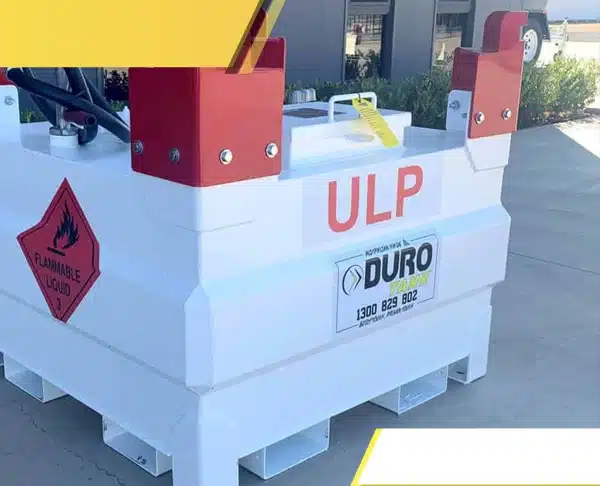

New regulations surrounding chemical classification were also introduced with the amendment with a globally harmonised classification system. This makes fuel storage easier and safer as there is a greater transparency about the specific type of flammable and combustible liquid and its relevant storage containers.

How Durotank can help

Durotank offers a wide range of premium quality on-site fuel storage solutions, including bulk fuel storage tanks from 250L – 100,000L sizes. Our solutions are 100% Australian designed and made, built to manage the harsh rural conditions. We offer tanks in a range of sizes that comply with the AS1940 standard so you can be assured of quality. Get in touch with our friendly team to find out more on 1300 829 802.

Durotank Superior Bulk Fuel Storage Solutions Standing as Australia’s premier manufacturer of superior bulk fuel storage solutions, Durotank manufactures 100%…

For safety, efficiency and sustainability in your operations, Durotank is your trusted partner when it comes to Poly Diesel Trailers.…

When it comes to fuel storage solutions, Durotank stands out as an industry leader when it comes to self bunded…

Farm fuel tanks play an essential role in the smooth operational running of a farm. They help ensure farm machinery…

The transport industry is the backbone of an efficient supply chain process. To best streamline this process, trucks need to…

The Australian Summer brings with it challenges of harsh, hot, and dry weather, which increases the need for accessible water…

Importance of Reliable Fuel Storage in Remote and Industrial Settings In remote and industrial settings correct fuel storage is crucial…