Cleaning and maintaining Fuel Tanks

Cleaning and Maintaining Fuel tanks: How to keep your fuel storage tanks at their best over summer and all year round

Keeping your fuel storage tank properly maintained is the most cost-effective way of getting effective long-term use. It is important to maintain tanks to ensure lasting engine wear, extending equipment use, preventing algae growth, ensuring better fuel quality for a more efficient engine and prevention of corrosion. Knowing the key signs, helps to prevent any issues with your fuel tanks. Issues that are to be actively avoided are microbial contamination and sludge both compromising fuel quality. Microbial contamination is harmful bacteria growth causing lower fuel quality and the blockage/damage of fuel filters. Similarly, sludge needs to be avoided as any break off will clog fuel filters and openings within the system.

Maintenance signs

To ensure your fuel storage tank is properly maintained, keep your eye out for warning signs that highlight when cleaning needs to be taken. These include any smell of sulphur or rotten odours, outlet valve drop rate drops, visible debris within the fuel. It is also important to be extra vigilant when there is a long time between last use, or if switching between fuel types. Understanding the signs of when maintenance is due is an effective prevention strategy for long term issues. There are a range of maintenance and cleaning tools that you can use to keep your tank in the best possible condition.

Regular Inspection of fuel tanks

Regular inspection of fuel tanks is an easy and effective way to keep your tank in peak condition. It is recommended that a monthly inspection is conducted, and any potential changes monitored. The presence of water especially needs to be checked with anything more than an inch of water removed within 30 days of the find. After heavy rainfall it is recommended especially that examination for water is undertaken as especially for self-bunded fuel tanks the tank needs have 110% of inner tank capacity. To remove water and decontaminate fuel using multipoint water pumping, effectively filtering fuel, undergoing non-entry tank cleaning and disposing of tank bottom water properly should all be considered. Within these inspections there should also be cross checks against the overfill protection device and shut-off valves to ensure proper use.

Using cleaning agents such as Ethanol will loosen any possible sludge or scale present within the tank and disperse water as it condenses in a diesel/ethanol blend tank. For safety issues such as if there is fuel leakage and fire danger a trained technician should oversee cleaning. Cleaning needs to entail complete drainage of gas, moisture and liquid. Both the internal and external walls and features of the tanks needs to be thoroughly scrubbed with industrial cleaners, with the type of cleaner varied based on fuel type. Tanks also need to be thoroughly washed/rinsed after scrub to ensure no trace of cleaner is left. Vents also need to be properly fitted especially within hotter temperatures to prevent high pressure within tank. Tightened fittings and clean vents are needed to prevent build up of sediments and physical materials. Also consider the importance of fuel heaters in maintaining fuel viscosity to prevent damage of heaters and reduce risk of fire, spillage or wax formation. Having clear and visible instructions also ensures that improper use of the tanks doesn’t occur, also that security numbers are legible.

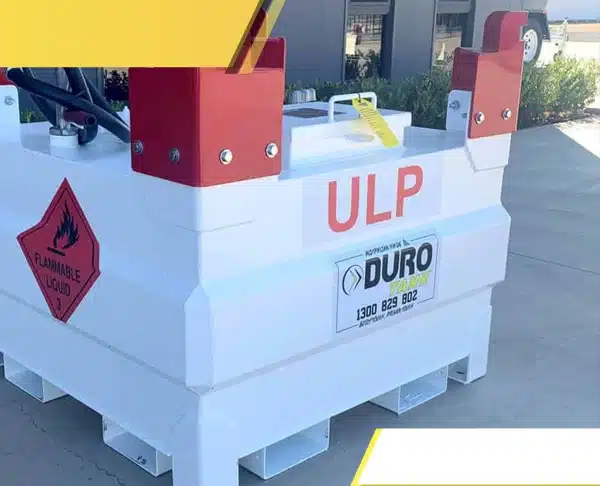

How Durotank Can Help

We offer an extensive range of bulk storage fuel tanks including single wall and self bunded fuel tanks, that provide practical storage across many industries. Our premium fuel storage solutions provide maximum safety and durability whilst the quality of the materials and build ensures minimal maintenance and cleaning is required. Get in touch with our team today to see how we can assist your organisation with their fuel storage needs 1 300 829 802

Durotank Superior Bulk Fuel Storage Solutions Standing as Australia’s premier manufacturer of superior bulk fuel storage solutions, Durotank manufactures 100%…

For safety, efficiency and sustainability in your operations, Durotank is your trusted partner when it comes to Poly Diesel Trailers.…

When it comes to fuel storage solutions, Durotank stands out as an industry leader when it comes to self bunded…

Farm fuel tanks play an essential role in the smooth operational running of a farm. They help ensure farm machinery…

The transport industry is the backbone of an efficient supply chain process. To best streamline this process, trucks need to…

The Australian Summer brings with it challenges of harsh, hot, and dry weather, which increases the need for accessible water…

Importance of Reliable Fuel Storage in Remote and Industrial Settings In remote and industrial settings correct fuel storage is crucial…